Recent Publications

2025

- Jaya Baranwal, Danila Merino.

- ACS Materials Au.

- https://doi.org/10.1039/D5GC00643K

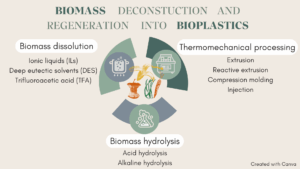

Abstract:This Review highlights cutting-edge strategies for transforming agricultural residues into bioplastics, offering a sustainable alternative to conventional petroleum-based plastics. By focusing on the deconstruction and reassembly of nonedible agro-wastes, these methods address critical challenges such as resource competition, plastic pollution, and greenhouse gas emissions. Key techniques reviewed include biomass dissolution, hydrolysis, and thermomechanical processing, with particular emphasis on the use of greener solvents such as ionic liquids (ILs) and deep eutectic solvents (DES). These approaches demonstrate significant potential for minimizing waste, improving resource efficiency, and enabling circularity in bioplastic production. The Review also critically examines current limitations, including solvent toxicity, scalability, and economic feasibility, while identifying promising directions for future research. By integrating innovative deconstruction techniques with sustainable manufacturing practices, this work aims to unlock the full potential of agricultural residues, paving the way toward a zero-waste, biobased economy.

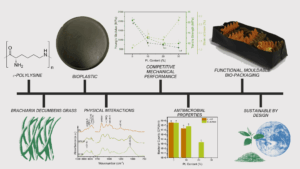

- José David Estrada-Sotomayor, Łukasz Łopusiewicz, Erlantz Lizundia, Sebastian Guenther, Danila Merino.

- Green Chemistry, 27(17), 4587-4602.

- https://doi.org/10.1039/D5GC00643K

Abstract: The environmental impact of non-degradable single-use plastics poses a significant challenge to current sustainability efforts. To foster a sustainable circular economy, this study introduces grass biomass as a renewable resource for the production of innovative bioplastics. The research involves the direct conversion of grass waste into composite bioplastics through alkaline hydrolysis, offering a transformative approach to plastic manufacturing. The hydrolysis process was optimized by varying treatment times and alkaline concentrations, with the ideal conditions identified as 1 M NH3 and 24 hours of treatment. Subsequently, the incorporation of ε-polylysine (PL) enhanced the mechanical properties of the bioplastics by acting as a plasticizer. Mechanical testing revealed that samples containing 10% and 20% PL exhibited comparable rigidity, with a Young’s modulus of approximately 700 MPa and a tensile strength of 10 MPa. Moreover, the addition of PL, up to 20%, significantly improved the water resistance of the bioplastics, evidenced by decreased moisture content and water solubility. Additionally, the bioplastics demonstrated effective antimicrobial activity against Escherichia coli and Staphylococcus aureus, as well as significant antioxidant activity. Life cycle assessment (LCA) and life cycle costing (LCAA) results demonstrate the potential environmental benefits of manufacturing grass biomass into plastic films, with a significant reduction in greenhouse gases, cumulative energy demand (CED), and cost when compared to benchmark packaging plastics. These promising properties indicate that these biomaterials could be effectively utilized in real-world applications, with potential application as sustainable biobased packaging materials.

- Tansu Abbasoglu, Xabier Lopez de Pariza, Gabriel Perli, Danila Merino, Phœbé Caillard-Humeau, Antoine Duval, Luc Avérous, Lourdes Irusta, Alba González, Haritz Sardon.

- Green Chemistry, 27(16), 4341-4351.

- https://doi.org/10.1039/D4GC06429A

Abstract:Escalating environmental concerns driven by the continuous demand for fossil-based materials have sparked growing interest in designing biobased polymeric materials for high-added-value applications. A novel series of self-blowing polycarbonate foams derived from various biobased polyols (e.g. cashew nutshell liquid, vegetable oil, and lignocellulose) is reported by leveraging thiol-triggered carbon dioxide release in a formulation composed of a thiol and 5- and 6-membered cyclic carbonates. The polyol architecture enabled a tunable open-cell morphology and properties, achieving up to 41 wt% biobased content, marking the first incorporation of biobased monomers in this type of foam. In this context, cashew nutshell-based foam featured good cyclic endurance at 70% compression and a high-water uptake capacity of 8 g g−1. As a forward-looking solution to address environmental challenges, this foam effectively supports the germination of different types of vegetable seeds (e.g. bok choy (Brassica rapa chinensis), lettuce (Lactuca sativa), and radish (Raphanus sativus)) in soilless environments, and its hydrolytic stability ensures reusability for subsequent seedling growth. This study lays the foundation for designing future environmentally friendly and renewable polymeric foams that are potentially recyclable with sustainable applications, e.g., in hydroponics.

- Matias Menossi, María Florencia Salcedo, Danila Merino, Vera Alejandra Alvarez, Romina Paola Ollier Primiano.

- Functionalized Nanoclays (pp. 387-405). Elsevier.

- https://doi.org/10.1016/B978-0-443-15894-0.00018-5

Abstract:The existing agricultural practices depend deeply on pest management. Traditional pesticides exhibit several disadvantages related to their low efficiency and high loss into water bodies, producing environmental pollution, increasing pesticide resistance to target species, reducing beneficial insects, and placing the health of producers and consumers at risk. Therefore, new approaches were recently developed to address this important issue. In this sense, one of the most relevant advances consists of using nanotechnology to create new materials to manage plant diseases related to bacteria, fungi, and flowering plant parasites infections, herbivorous insects, among others, in a controlled/sustained-release manner.

In the last decades, nanoclays (NCs) have gained increasing popularity to develop materials useful for sustainable agricultural practices. These materials exhibit interesting properties, and they can be custom-modified or functionalized because of their versatile structure and biocompatibility, added to their natural availability and low cost. Thus, the aim of this review is to summarize different emerging nanotechnological strategies based on functionalized NCs to fight against plant pathogens, insects, and pests with emphasis on the increase in crop production together with the care of the environment and human health. This review also highlights the innovative and ecological use of clay-based nanocarriers to stimulate the immune system of plants. Additionally, it discusses the challenges and future perspectives related to these promising systems.

2024

- Ana Isabel Quilez-Molina, Jonatan Niño Sanchez & Danila Merino

- Nature Communications, 15(1), 9158.

- https://doi.org/10.1038/s41467-024-53468-y

Abstract: The growing global food demand, coupled with the limitations of traditional pest control methods, has driven the search for innovative and sustainable solutions in agricultural pest management. In this review, we highlight polymeric nanocarriers for their potential to deliver double-stranded RNA (dsRNA) and control pests through the gene-silencing mechanism of RNA interference (RNAi). Polymer-dsRNA systems have shown promise in protecting dsRNA, facilitating cellular uptake, and ensuring precise release. Despite these advances, challenges such as scalability, cost-efficiency, regulatory approval, and public acceptance persist, necessitating further research to overcome these obstacles and fully unlock the potential of RNAi in sustainable agriculture.

- Chiara Gnocchi, Martina Lenzuni, Fabrizio Fiorentini, Danila Merino, Maria Summa, Lorne Golub, Hsi-Ming Lee, Francis Johnson, Rosalia Bertorelli, Giulia Suarato, Athanassia Athanassiou

- Journal of Drug Delivery Science and Technology, 101, 106155.

- https://doi.org/10.1016/j.jddst.2024.106155

Abstract:Wound healing is a delicate process comprising various phases, of which inflammation constitutes the most critical one, as some wounds fail to evolve from this state due to pre-existing pathologies or medical conditions, becoming chronic and causing pain and serious consequences for the patients. Given this context, innovative strategies able to support the body in the transition through the inflammatory and the proliferative phases are needed. Here, we propose to deliver to the wound zein microparticles (ZμP) loaded with chemically modified curcumin (mCUR), a novel bioactive molecule with strong antioxidant properties. Derived from the classic curcumin, mCUR chemical structure has been modified with an amino phenyl carbonyl group on C4to overcome the poor bioavailability in the human body and to reach stronger inhibition of inflammatory markers thanks to a higherin vitroefficacy (lower IC50). ZμP were fabricated via spray drying starting from various zein/mCUR ratios. An exhaustive characterization of the physico-chemical properties of ZμP, either empty or loaded, has been carried out, alongside with bioactivity assessments via human keratinocytes andEscherichia colicultures. All the formulations presented average diameters of 1 μm, resulted biocompatible, and led to an encapsulation efficiency in the range of 78.1–83.0 %. Finally, antioxidant properties of loaded microparticles were assessed via DCFH-DA assay, where a fluorescence decrease proportional to mCUR concentration was clearly visible (down to 41.7 %). These promising results highlight our formulations’ ability to reduce oxidative stress inside the cells, representing a promising strategy to address the problem of chronic wounds, supporting the body in overcoming the inflammatory stage.

- Danila Merino

- ACS Materials Au, 4, 450-458.

- https://doi.org/10.1021/acsmaterialsau.4c00031

Abstract: In the 21st century, global agriculture confronts the urgent challenge of increasing food production by 70% by 2050 while simultaneously addressing environmental and health concerns. Plastics, integral to agricultural innovation, present sustainability challenges due to their non-biodegradable nature and contribution to pollution. This perspective examines the transition to bioplastics, emphasizing their bio-based origin and their crucial characteristic of being readily biodegradable in the soil. Key bioplastics such as poly(lactic acid) (PLA), polyhydroxyalkanoates (PHAs), and biomass-derived polymers are discussed, particularly regarding the microplastic generation in soil resulting from their use in specific applications like mulch films, delivery systems, and soil conditioners. Embracing bioplastics signifies a significant step forward in achieving sustainable agriculture and addressing plastic waste. However, it is highlighted that while some bioplastics can be recovered and recycled, special applications where the plastic is in intimate contact with soil pose challenges for recovery. In these cases, that represent more than the 50% of plastics used in agriculture, meticulous design for biodegradation in soil synchronized with agricultural cycles is necessary. This approach ensures minimal environmental impact and promotes a circular approach to plastic use in agriculture.

- Ana Isabel Quilez-Molina, Danila Merino, Michel Dumon

- Food Hydrocolloids, 154, 110114.

- https://doi.org/10.1016/j.foodhyd.2024.110114

Abstract: In line with the growing demand for more sustainable and efficient materials for food packaging, new bifunctional pH-responsive composites were developed with the dual purpose of packaging and indicating seafood spoilage. Within this study, a fully bio-based composite based on porous starch (PS) was prepared via microwave irradiation (1 g/cm3) followed by functionalization via dip-coating with an active solution of anthocyanins-carboxymethyl cellulose (CMC). Here, the edible anthocyanins (Ath) endowed excellent antioxidant and pH-sensing properties to the resulting bifunctional composite (PS-ACMC), covering a pH range of 6–11.5, making it compelling for developing smart food-packaging materials. Moreover, results indicated that the coating scarcely altered the excellent mechanical properties developed by the PS sample, which were comparable with the commercial expanded polystyrene foams. Concurrently, to enhance the competitive properties of the starch component, bifunctional PS-CMC systems were devised crosslinking starch with citric acid. The obtained citrate-starch specimens exhibited a superior porous structure with lower density (0.61 g/cm3), antioxidant properties, and about 40% less solubility in water compared to the neat starch sample. Remarkably, this functionalization hindered the colour-switching properties when the active coating was added, likely due to a strong fixation of the CMC with the natural dye. However, PS-ACMC composites exhibited a rapid and effective colour response, transitioning from violet to greenish-blue, facilitating visual and real-time assessment of the freshness when using shrimp as test specimens. The results reported underscored the high potential of such bifunctional biocomposites in obtaining sustainable and smart freshness-monitoring packaging for seafood.

- Danila Merino, Paolo Bellassi, Lorenzo Morellib, Athanassia Athanassiou

- Data in Brief, 54, 110490.

- https://doi.org/10.1016/j.dib.2024.110490

Abstract: This article presents analyzed data on the antimicrobial, barrier, and mechanical properties inherent to films created by blending carrot pomace with wheat gluten and polyglycerol-3 plasticizer and combined with varying contents (0 wt.%, 3 wt.%, and 5 wt.%) of eugenol, a natural antimicrobial compound derived from essential oils. The integration of carrot pomace, wheat gluten, plasticizer, and eugenol involved meticulous mortar and pestle processing, ensuring a homogenous blend. Subsequently, the mixture was compression-molded in a hydraulic press to fabricate the films. Standard bacteria strains—Escherichia coli ATCC 25922 and Staphylococcus aureus ATCC 6538—are used in the antimicrobial evaluation, and antimicrobial efficacy is measured using OD600 measurements. Water vapor permeability (WVP) measurement effectively defines the films’ potential to prevent water vapor infiltration. Mechanical properties are assessed by determining elastic modulus, tensile strength, and elongation at break, which together reveal the films’ adaptive flexibility and durability. The dataset presented herein holds substantial promise for food packaging applications. Researchers in the food packaging industry can leverage the antimicrobial and barrier property data to design novel packaging materials, potentially enhancing shelf-life and food safety. Engineers and material scientists can utilize the mechanical properties data to develop structurally robust and flexible materials.

- Danila Merino, Uttam C. Paul, Athanassia Athanassiou

- Food Hydrocolloids, 109903.

- https://doi.org/10.1016/j.foodhyd.2024.109903

Abstract:The proliferation of petroleum-derived plastics has led to environmental concerns, prompting the exploration of sustainable alternatives. This study deals with the development of natural polymeric composite materials that can be used as alternatives to conventional plastics. In particular, biocomposite films were prepared by hot pressing a blend of carrot pomace (CP) with 10, 30 and 50 wt% of two vegetable proteins: wheat gluten (Gn) and zein (Z), for the optimization of the final properties of the developed biomaterials. The resulting composites exhibit improved physicochemical, morphological, and thermal properties and provide enhanced water resistance compared to CP-only bioplastics, while in particular, the ones prepared with Gn, exhibited also improved optical and mechanical properties, making Gn composites best candidates for a larger number of applications. Further optimization was achieved by adding 10 wt % polyglycerol plasticizer to the CP-50 wt% Gn composites, resulting in even better mechanical and oxygen barrier properties. These biocomposites show great potential for food packaging, offering mechanical resistance (elastic modulus of 244.9 ± 25.3 MPa and tensile strength of 10.1 ± 0.7 MPa), flexibility (elongation at break of 24.7 ± 5.7%), high transparency and optical clarity, effective UV-blocking in the 200–350 nm range, excellent antioxidant activity (3.4 μmol Trolox/g) and water vapor (1.3 × 10−9 g s−1 m−1 Pa−1) and oxygen (296.1 ± 1 cm3 μm m−2 day−1 atm−1) barrier properties. Additionally, they exhibit low migration of components into food simulants (6.7 ± 0.6 mg dm−2) and fast biodegradation in soil (83% after 30 days). The findings reported in this manuscript motivate the adoption of eco-friendly materials and represent a significant step towards a sustainable future.

2023

- Danila Merino & Athanassia Athanassiou

- Advanced Sustainable Systems, 7(9), 2300179.

- https://doi.org/10.1002/adsu.202300179

Abstract: Byproducts of the processing of foods are usually non-edible residues that are typically discarded, even though they contain large amounts of natural polymers with great potential in bioplastics and biocomposites preparation. Herein, a new method of production of vegetable-waste-derived biocomposites is developed. It consists of the thermomechanical processing of different residues in the presence of small amounts of water, representing an advancement in the state-of-the-art in the complete conversion of fruit and vegetable biomass into biocomposites. In particular, carrot pomace (CP) is processed by compression molding at different temperatures, pressures, and times. Selected processing conditions are also applied to other food processing byproducts. The morphological, mechanical, barrier, optical, and antioxidant properties of the obtained biocomposites and their interaction with water in terms of moisture content, water solubility, and moisture absorption are reported here. Results indicate that biocomposites obtained by this method present similar properties compared to biocomposites prepared by acid or alkaline hydrolysis of biomass reported in the literature, but still inferior compared to bioplastics currently in the market. Improvements in the materials’ interaction with water are highlighted here as the necessary next step to achieving the transition toward greener bioplastics.

- Danila Merino & Athanassia Athanassiou

- Chemical Engineering Journal, 454, 140171.

- https://doi.org/10.1016/j.cej.2022.140171

Abstract: Mild acid hydrolysis of various plant residues has been proposed in recent years as a novel way of transforming biomass into bioplastics. However, the alkaline hydrolysis of such residues has not yet been studied for this purpose. In this work, an in-depth comparative study is carried out for the first time on the physicochemical, thermal, mechanical, and morphological aspects of the bioplastics produced by acid and alkaline hydrolysis starting from two different plant residues: spinach stems (SS) and peanut shells (PS). The chemical treatments followed here, produced self-standing SS bioplastics and hydrolyzed PS powders that were incorporated as fillers in a thermoplastic starch (TPS) matrix to obtain composites. The alkaline hydrolysis led to bioplastics with superior mechanical and barrier properties than those obtained from acid hydrolyzed biomass. The Young’s modulus (YM) of SS-bioplastics produced upon alkaline hydrolysis, tripled, their tensile strength (TS) almost doubled, and their water vapor permeability (WVP) was reduced by 15%, compared to SS-bioplastics produced upon acidic hydrolysis. TPS-alkali hydrolyzed PS composites showed increments of 22% in YM, 10% in TS, and a reduction of about 30% in their WVP compared to the respective acid hydrolyzed composites. The physicochemical, thermal, and morphological analysis confirmed that the main cause of these improvements was cellulose nanofibrillation, which was favored by the greater efficiency of the alkaline medium to hydrolyze the pectin, hemicellulose, and lignin polymers. This research represents a step ahead in understanding the processes of transforming non-edible vegetable wastes into sustainable bioplastics and comes in a critical moment when an urgent transition towards a circular economy is need, and industrial processes are expected to reduce their carbon footprint and generate zero waste.

- Danila Merino, Andrea Yamila Mansilla, María Florencia Salcedo, Athanassia Athanassiou

- ACS Sustainable Chemistry & Engineering, 11(29), 10917-10928.

- https://doi.org/10.1021/acssuschemeng.3c02992

Abstract: In this work, agar (Aa)-based hydrogels were developed incorporating different concentrations of orange peel (OP) particles, pretreated using three different methods (hydrolysis, ultrasonication, or simple suspension in hot water), and 1.5 wt % limonene (LMN), to be tested as active soil conditioners for agriculture. The results of swelling of these hydrogels in distilled and tap water showed that acid hydrolysis or ultrasonication pretreatments of OP are counterproductive and that the simplest and lowest-energy method of OP pretreatment resulted in the most efficient hydrogels in terms of swelling. The incorporation of LMN into the Aa-based hydrogels increased their swelling capacity in tap water, while the incorporation of OP particles in the Aa+LMN hydrogels increased the number and decreased the size of their pores but did not significantly influence their swelling capacity, which ranged from 650 to 700% after 4 h of immersion. The hydrogels developed here were prepared with up to 50 wt % OP particles due to the increased water solubility for higher concentrations. The biopesticide activity of the hydrogels was investigated against the bacterium Pseudomonas syringe pv tomato DC3000 (Psy) and the necrotrophic fungus Fusarium solani f. sp. eumartii (F. eumartii), while the ability of the hydrogels as soil conditioners to retain soil moisture under simulated drought conditions was exploratorily investigated in tomato plants. The results demonstrate that even if the hydrogels did not show biopesticide activity against the studied microorganisms, the addition of 2.5 wt % hydrogel to the substrate significantly increased the moisture content of the soil and consequently improved the relative water content of tomato leaves under drought stress.

- Amirsoheil Honarbari, Pietro Cataldi, Arkadiusz Zych, Danila Merino, Niloofar Paknezhad, Luca Ceseracciu, Giovanni Perotto, Marco Crepaldi, Athanassia Athanassiou

- ACS Applied Electronic Materials, 5(9), 5050-5060.

- https://doi.org/10.1021/acsaelm.3c00799

Abstract:Printed circuit boards (PCBs) physically support and connect electronic components to the implementation of complex circuits. The most widespread insulating substrate that also acts as a mechanical support in PCBs is commercially known as FR4, and it is a glass-fiber-reinforced epoxy resin laminate. FR4 has exceptional dielectric, mechanical, and thermal properties. However, it was designed without considering sustainability and end-of-life aspects, heavily contributing to the accumulation of electronic waste in the environment. Thus, greener alternatives that can be reprocessed, reused, biodegraded, or composted at the end of their function are needed. This work presents the development and characterization of a PCB substrate based on poly(lactic acid) and cotton fabric, a compostable alternative to the conventional FR4. The substrate has been developed by compression molding, a process compatible with the polymer industry. We demonstrate that conductive silver ink can be additively printed on the substrate’s surface, as its morphology and wettability are similar to those of FR4. For example, the compostable PCB’s water contact angle is 72°, close to FR4’s contact angle of 64°. The developed substrate can be thermoformed to curved surfaces at low temperatures while preserving the conductivity of the silver tracks. The green substrate has a dielectric constant comparable to that of the standard FR4, showing a value of 5.6 and 4.6 at 10 and 100 kHz, respectively, which is close to the constant value of 4.6 of FR4. The substrate is suitable for microdrilling, a fundamental process for integrating electronic components to the PCB. We implemented a proof-of-principle circuit to control the blinking of LEDs on top of the PCB, comprising resistors, capacitors, LEDs, and a dual in-line package circuit timer. The developed PCB substrate represents a sustainable alternative to standard FR4 and could contribute to the reduction of the overwhelming load of electronic waste in landfills.

- Ana Isabel Quilez-Molina & Danila Merino

- Advanced Applications of Biobased Materials. Food, Biomedical, and Environmental Applications 2023, Pages 61-110

- https://www.sciencedirect.com/science/article/abs/pii/B9780323916776000234

Abstract: Plant biomass is the most abundant renewable resource on Earth and the most promising substitute for petroleum feedstock. It is the source of polymers such as cellulose, starch, pectin, and other active compounds with antioxidant and antimicrobial properties. Although plant-biomass-derived polymers have been used to prepare bioplastics for more than a century, forefront methods for biomass deconstruction and reassembling into biocomposites have recently been proposed. These methods are expected to significantly impact the future since their use in new value-added products complies with the zero waste and circular economy principles. This chapter offers an updated overview of the traditional and emerging methods used to convert vegetable wastes into sustainable plant-based bioplastics. In addition, we outline some challenges and future research directions needed to explore their full potential.